-

WhatsApp / Mob : +86 156 5177 2521

-

o email : mrwin@cnbangwin.com

WhatsApp / Mob : +86 156 5177 2521

o email : mrwin@cnbangwin.com

PSA Hydrogen Generator for High Purity On-Site Hydrogen

Oct 21 , 2025

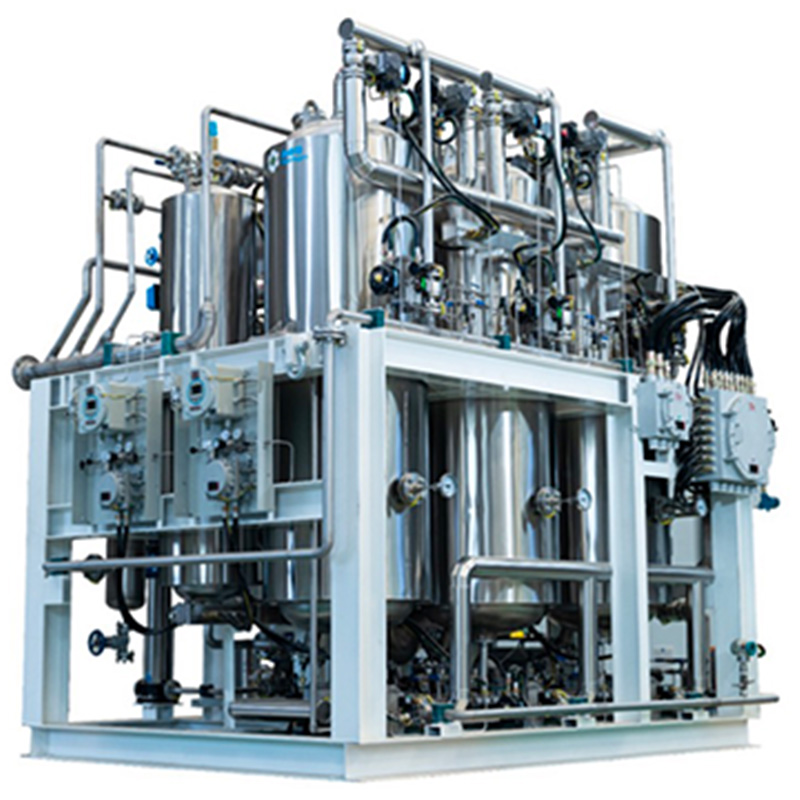

The PSA Hydrogen Generator (Pressure Swing Adsorption) is a continuous hydrogen production system for on-site generation.

It is based on PSA technology to separate high-purity hydrogen from feed gases like reformate or natural gas. The system has a stable operation, low energy consumption, and simple maintenance, and can meet the requirements of various industrial fields that need a continuous supply of hydrogen.

l Product Name: PSA Hydrogen Generator

l Technology: Pressure Swing Adsorption (PSA)

l Hydrogen Purity: up to 99.999%

l Capacity: 5–5000 Nm³/h

l Operating Pressure: 0.1–3.0 MPa

l Applications: Chemical, Metallurgy, Electronics, Food, Glass, Energy

l Certification: ISO, CE

l Control: Fully automatic PLC system

l High hydrogen purity (up to 99.999%)

l Stable performance with continuous production

l Low energy consumption and economical to operate

l Fully automatic control system

l Modular and compact design, easy installation

l Low maintenance and long service life

l Fast start-up time

|

Parameter |

Specification |

Unit |

|

Hydrogen Purity |

99.9–99.999 |

% |

|

Capacity |

5–5000 |

Nm³/h |

|

Operating Pressure |

0.1–3.0 |

MPa |

|

Dew Point |

≤ –60 |

°C |

|

Technology |

PSA |

— |

|

Control System |

PLC Automatic |

— |

|

Installation Time |

20–45 |

Days |

l Provides on-site hydrogen supply, no need for transportation or storage of cylinders.

l Delivers high-purity hydrogen up to 99.999%, which can meet the strict requirements of the electronics industry and chemical hydrogenation reactions.

l Energy-saving optimized PSA system with low power consumption.

l Safe and reliable with multiple built-in safety controls and alarms.

l Customizable according to the customer’s demand of capacity and output pressure.

l Environmentally friendly clean hydrogen production, zero emissions and pollution.

l Chemical Industry – hydrogenation, ammonia production

l Metallurgy – protective atmosphere, annealing

l Electronics – semiconductor manufacturing, etching

l Food Industry – hydrogenation of edible oils and fats

l Energy & Fuel Cells – clean hydrogen supply

l Glass Industry – protective gas atmosphere

l The PSA Hydrogen Generator separates hydrogen in mixed gas streams using selective adsorption on special adsorbents at high pressure.

l Feed gas is supplied to the adsorption columns.

l Impurities such as CO, CO₂, CH₄, and moisture are adsorbed by the adsorbents.

l Hydrogen is separated and produced as product gas.

l Adsorption columns are regenerated by reducing the pressure (swing adsorption).

l This cyclic operation provides a continuous supply of high-purity hydrogen.

l ISO 9001 Certified Manufacturing

l CE Certified Equipment

l 100% Performance Testing Before Delivery

l Skid-Mounted & Easy to Install

A1: Typical purity is from 99.9% to 99.999%, depending on system configuration.

A2: PSA is more suitable for large-scale production and has lower operating costs.

A3: It takes about 20–45 days depending on the capacity and site conditions.